Get 100% visibility and traceability in your manufacturing process

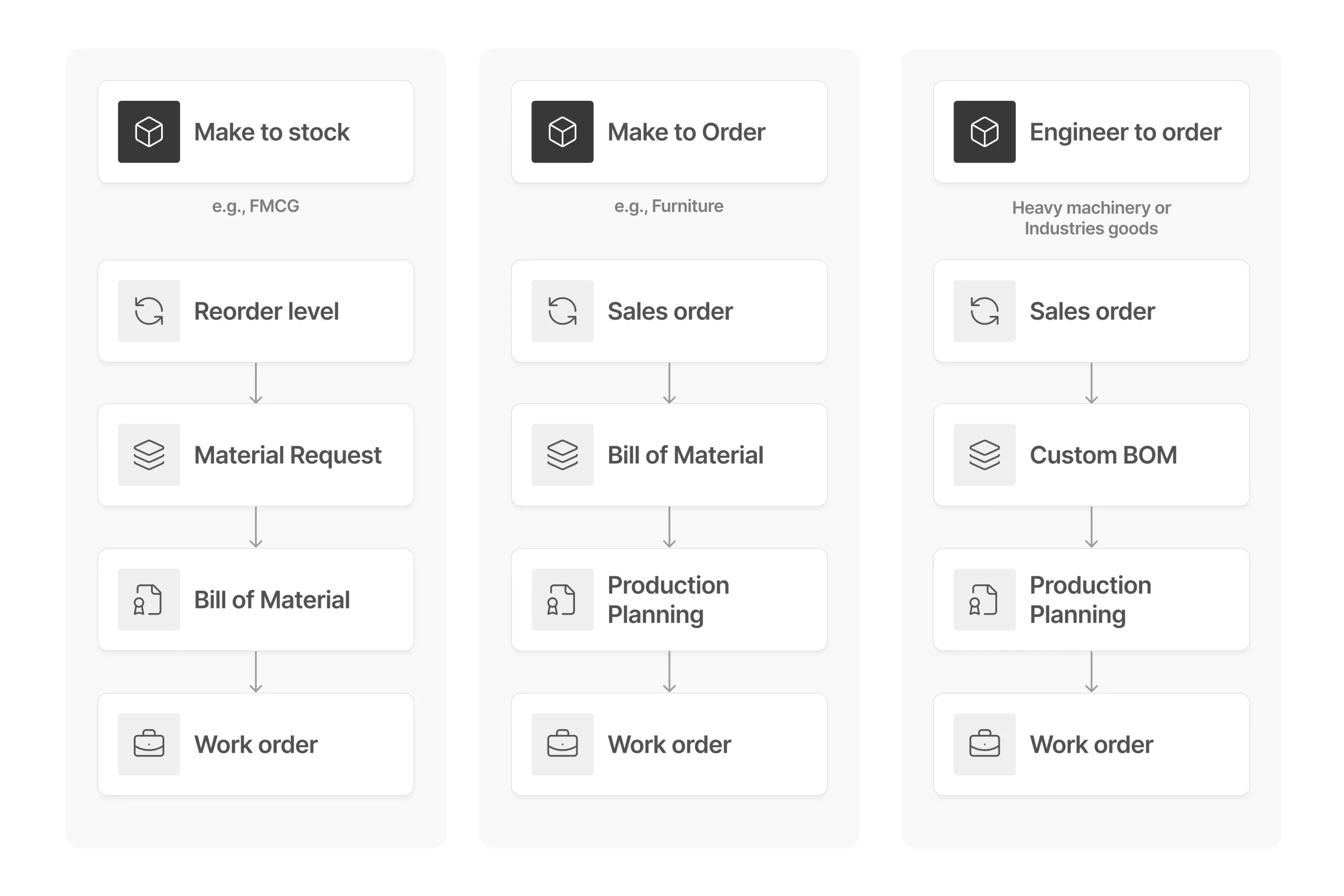

With TAGRIT ERP’s manufacturing module, you can track multi-level BOMs (Bill of Materials) for both finished goods and sub-assemblies. Integration with sales and stock ensures you stay ahead, anticipating upcoming production jobs and pre-planning your production queues. Estimate raw material requirements and initiate timely requisitions to keep things flowing. Ensure the accurate valuation of produced items, along with quality checks, before back-flushing is carried out.

Everything under one Roof

- Maintain BOM operations

- Production planning

- Work order

- Capacity planning

- Subcontracting

- Identify subcontracting items

- Subcontracting orders

- Subcontracting billing

- Manufacturing reports and dashboards

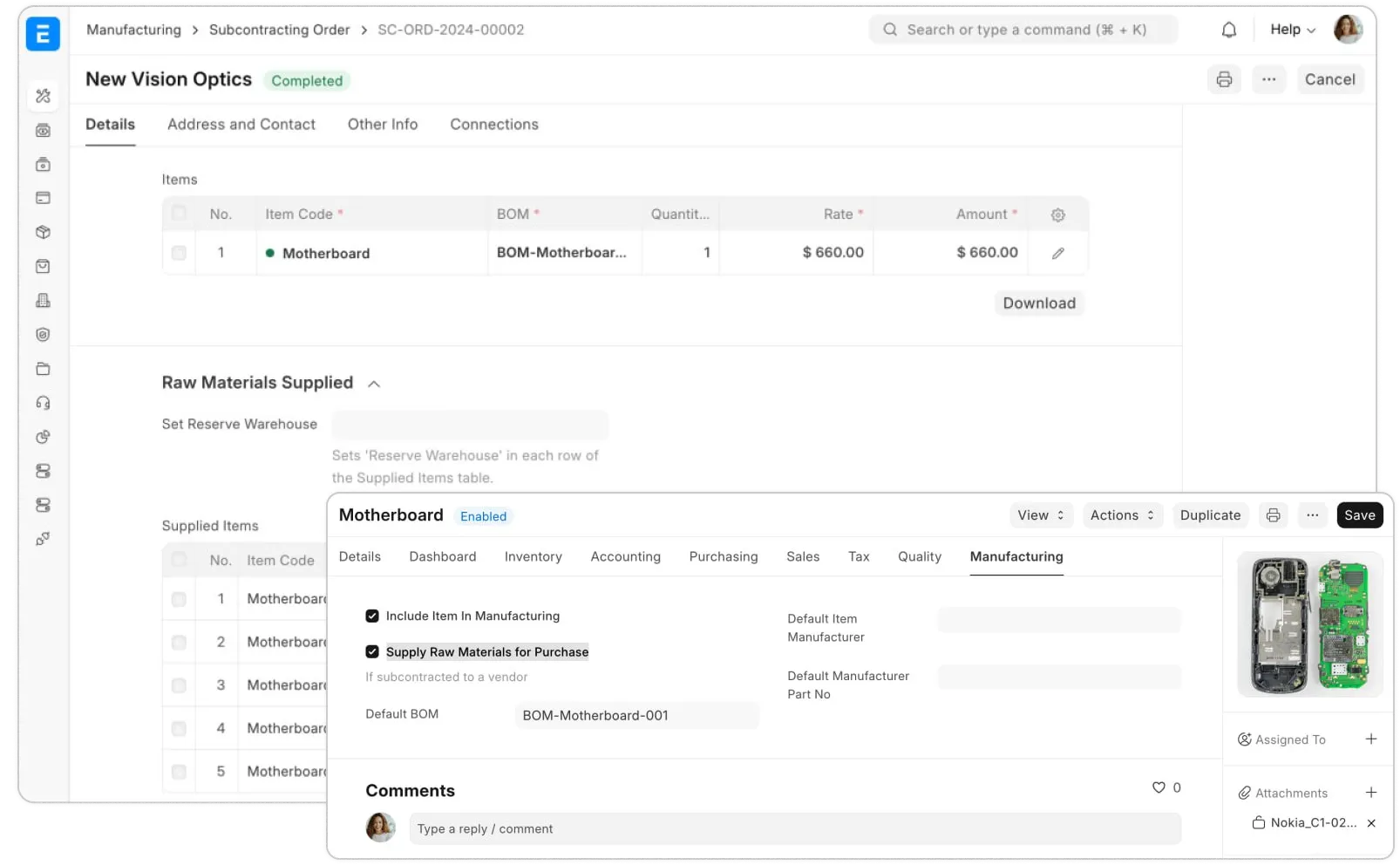

Subcontracting

Focus on what you do best and let subcontracting handle the rest. By partnering with experts, you can leverage your core competencies while outsourcing specific tasks. TAGRIT ERP simplifies this process by allowing you to mark items as subcontracted to suppliers and manage all subcontracting orders in one centralized system.

Track progress, ensure timely execution, and scale your subcontracting operations seamlessly. With TAGRIT ERP, you can efficiently collaborate with top suppliers, ensuring high-quality services while maintaining focus on your business strengths

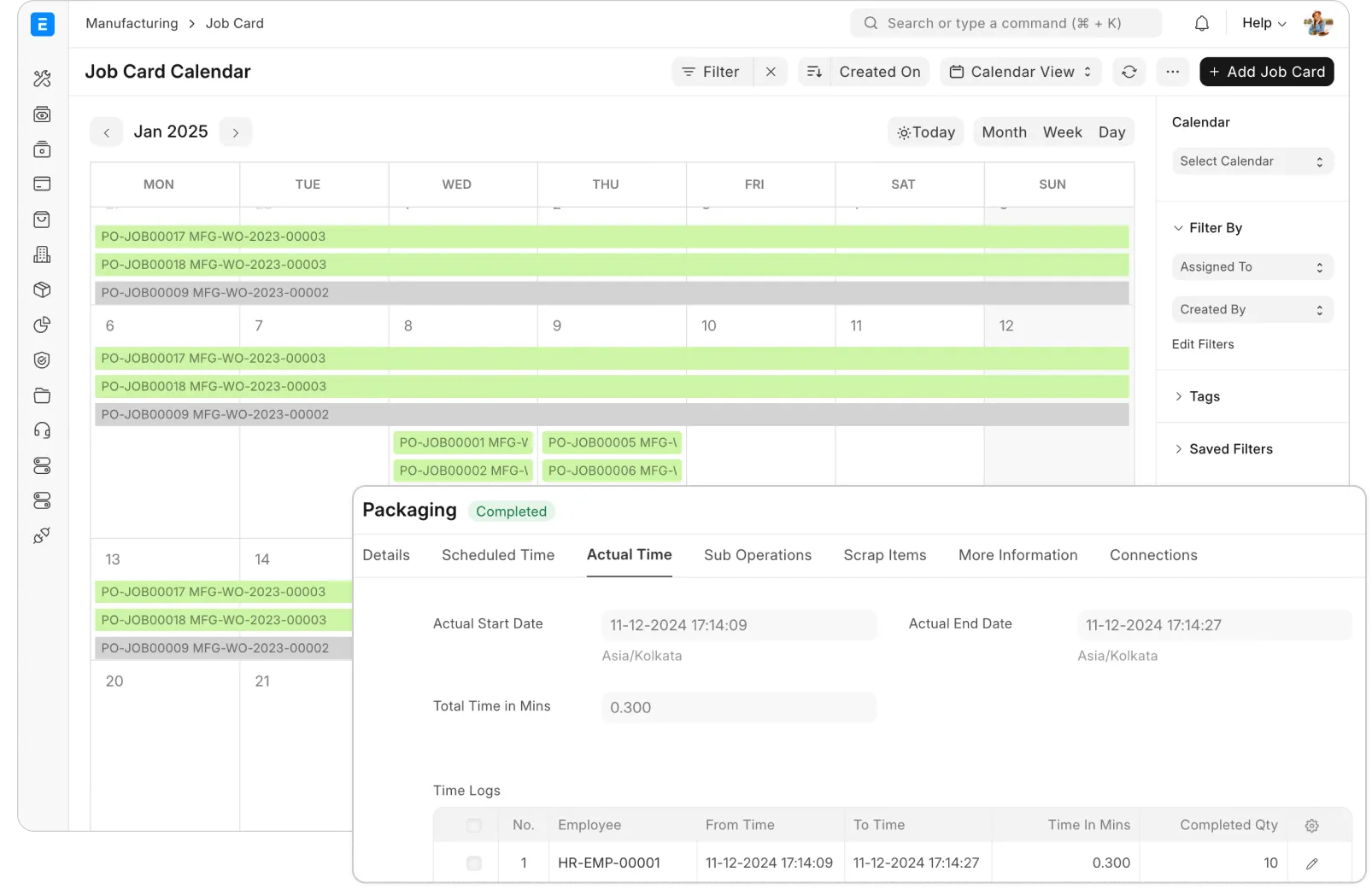

Capacity planning

Factory operating costs form a significant part of a company’s expenses. Hence, mismanaging production job allocation on Workstations can result in major losses. TAGRIT ERP’s capacity planning feature helps track workloads on each workstation, enabling efficient scheduling of future production jobs.

This ensures optimal utilization of resources, accelerates production, and helps fulfill delivery commitments on time.